Products Categories

Feature Products

0.38 To 2.45 mm Thickness Standard V Stud V Purlin Making Machine Line

What is the Steel Purlin Hat/C/U/Z/L Profile Channel 120mm Size C purlin Roll Forming Machine?

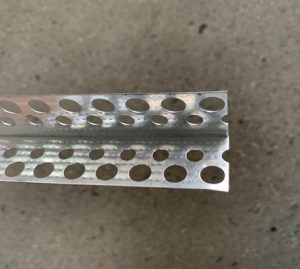

Steel Purlin Hat/C/U/Z/L Profile Channel 120mm Size C purlin Roll Forming Machine is widely used around the world. This galvanized keel forming machine have two forming lines, but they have seperated control systems, this kind of double line light gauge keel stud track steel roll forming machine will save the space for the factory. And the products this machine produced is mainly used for the drywall and theceiling structure. As a basic material, keel steel is widely used for many aspects as assistant supporters.

Machine Video

Machine Specification

| Part details | Item Name | Specification | ||

| Material | Raw material | Galvanized steel | ||

| Thickness | 0.3-0.8 mm | |||

| Machine | Roller station | 12 | ||

| Shaft diameter | 55 mm | |||

| Shaft material | 45# steel with 0.05mm chrome | |||

| Roller material hardness 30-40 HRC | Cr 12 | |||

| Machine size | About 6×1.3×1.3m | |||

| Machine weight | About 2.5ton | |||

| Machine color | As customer’ request | |||

| Working speed | 30-50 m/min | |||

| Cutter | Hardness | 50-65 HRC | ||

| Cutting tolerance | ± 1 mm | |||

| Material | Cr 12 | |||

| Operate | Hydraulic cutting | |||

| Power | Driving way | Chain 1 inch | ||

| Main power | 4 kw | |||

| Pump power | 3 kw | |||

| Voltage | 380v/50HZ,3P or customize as customer’ request |

|||

| Control system | PLC brand | Delta made in Twaiwan | ||

| Screen | Touchable screen | |||

| Language | Chinese and English or add language as customer need | |||

| Decoiler | Operation | Manual | ||

| Weight capicatity | 3 ton | |||

| Price | Free ! | |||

| Receiving table | Operation | Manual | ||

| Length | 3 m | |||

| Price | Free ! | |||

Machine Features

1) Good quality control

2) Highly competitive prices

3) state-of-art technology products

4) Best professional team of lifestyle consumer electronics.

5) Smooth communication

6) Effective OEM&ODM service

Packaging Type Of Bag

Machine Function

Customer should prepare before machine arrive:

1. Equipment feeding direction: left in and right out

2. Voltage parameters (380/50/60 three-phase 220/50/60 415/50/60 480/50/60)

3. Equipment molding: hydraulic cutting

4. Hydraulic oil: 46 # hydraulic oil

5. Gear oil: 18 # hyperbolic gear oil

6. Motor explosion-proof grade ExdIICT4

7. Motor protection grade IP55

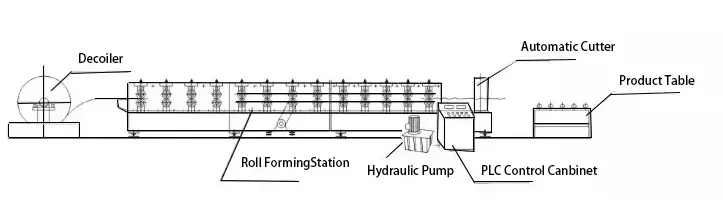

Whole processing line:

Electric Decoiler — Punchine Press–Feeder — Roller forming — Cutting — Receiving rack — Packing

Machine Option

Electric Decoiler

Horizontal feeding rack/Vertical feeding rack for choose as per final drawing.

Usually waved, corrugated, roof panel, double layer, 3- layer roll forming machine use horizontal feeding rack, cause feeding coil width 1000mm or 1250mm or 1500mm. But customized C Z U W L solar support frame profile small, feeding width usually 196mm, 125mm etc, vertical feeding rack better

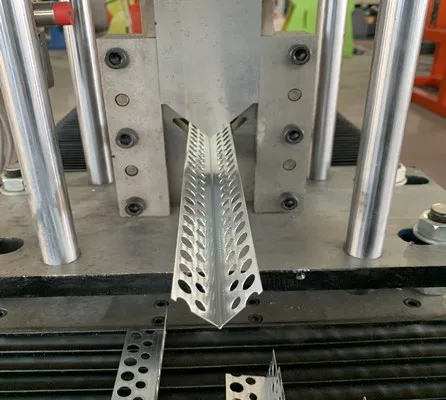

Cutter

Cr 12 molybdenum vanadium die steel hydraulic shearing, heavy-duty oil cylinder, double guide column design, longer service life, more stable machine. Can cut Galvanized/ Stainless/Copper/Aluminum sheet

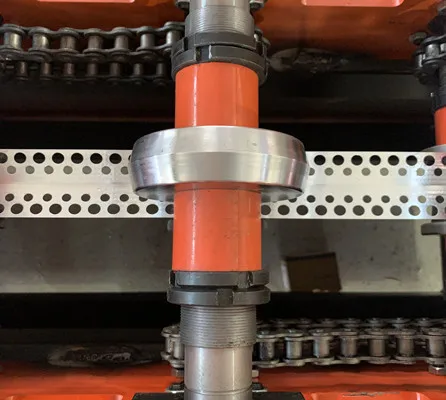

Roller

Bearing steel roller suitable for 0.2-1.5 mm thickness galvanized sheet – aluminum – copper Hard chrome plated surface

Chain transmission

1-inch sprocket chain hanging design is more beautiful, the shaft tension is more uniform

Hydraulic pump station

4 kW air-cooled hydraulic pump station Hydraulic station pressure in 10-12mpa plus 45 hydraulic oil Advantages: can be 24 hours uninterrupted work will not produce hydraulic pump station overheating phenomenon

Vertical liquid crystal electric cabinet

whole line using PLC control, LCD display touch screen, human-machine interface, to achieve the interaction between people and PLC.

Monitor equipment running status and fault indication in real time. Equipped with wired manual forward and backward.

Machine Application

Related Products

CONTACT US

Featured Categories

Contact Us

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

© Copyright – 2003-2023 : Zhengzhou Howann Machinery Co., Ltd All Rights Reserved.