Products Categories

Feature Products

2023 New Design Supermarket Shelf Making Machine Pallet Rack Roll Forming Machine Rack Making Machine

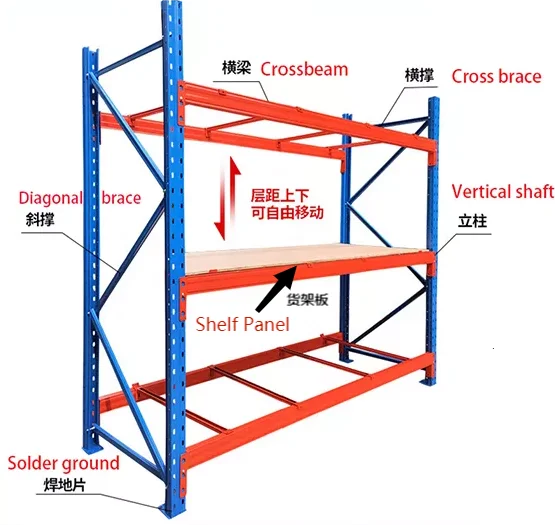

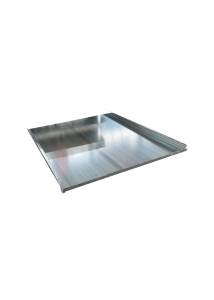

Shelf laminate (carrier) forming machine is a shelf laminate equipment used to produce one of the components of the shelf series. The finished product produced is “shelf laminate”. It is mostly used as a “shelf laminate” as one of the heavy-duty shelf components such as storage warehouses and logistics transportation.

Machine Video

Machine Specification

|

NO.

|

Name

|

QTY

|

Remark

|

|

1

|

5T hydraulic decoiler

|

1 set

|

Max 5T

Max coil:800mm Hydraulic expansion and motorizied decoiling |

|

2

|

Holes Punching & corner cut

|

4 sets

|

We use hydraulic punching machine

Corner cut mould:2 sets ( left and right side can be adjustable manually) Lateral holes punching mould: 1 set( position can be adjustable manually) |

|

3

|

Logo stamping

|

1 set

|

Stamping mould:1 set

|

|

4

|

Roll forming Machine

|

1 set

|

wall panel catilever structure

24 forming stations 15KW motor made in China |

|

5

|

Hydraulic Cutting&bending mould combination

|

1 set

|

Cutting power:7.5kw

Mould material:Cr12.HRC58-62 |

|

6

|

Run-out table

|

2pcs

|

Steel frame with Rollers

|

|

7

|

Electric control panel

|

1 set

|

PLC control system ,Siemens from German brand

Yaskawa inverter from Japan |

|

8

|

Hydraulic system

|

1 set

|

Solenoid is made in China

|

|

Suitable Material

|

Galvanized Steel Coil

|

|

Material Width

|

According to Profile Drawing

|

|

Material Thickness

|

0.8-1.2 mm

|

|

Roll forming speed

|

10-15 m/min (Exclude Punching & Cutting Time)

|

Machine Features

1. Good quality: We have a professional designer and experienced engineer team and the raw material and accessories we use are

good.

2. Good service: we provide the technical support for whole life of our machines.

3. Guarantee period: within one year since the date of finishing commissioning. The guarantee covers all the electric, mechanic

and hydraulic parts in the line except for the easy-worn parts.

4. Easy operation: All machine controlling by PLC computer controlling system.

5. Elegant appearance: Protect the machine from rust and the painted color can be customized

6. Reasonable price: We offer the best price in our industry.

Packaging Type Of Bag

Machine Function

Machine Option

final product

Machine Application

Related Products

CONTACT US

Featured Categories

Contact Us

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

© Copyright – 2003-2023 : Zhengzhou Howann Machinery Co., Ltd All Rights Reserved.