Products Categories

Feature Products

Aluminum ceiling panel machine trapezoid tile making machine Cladding sheet making machine

Machine Video

Machine Specification

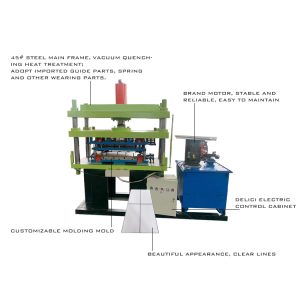

|

Model

|

400kn

|

|

Table effective area (mm)

|

600mm * 650mm

|

|

Table height(mm)

|

800mm

|

|

Opening Height(mm)

|

500mm

|

|

Cylinder Stroke(mm)

|

300mm

|

|

Nominal pressure (kn)

|

400kn

|

|

Four-column size(mm)

|

60mm chrome plated

|

|

Type of Electricel Control

|

Point and automatic 2 functions

Use electrical contact stroke control

|

|

Motor power (Kw)

|

5.5kW (pure copper core)

|

|

Control type

|

Stop fast. Press down with both hands.

Including photoelectric protection

|

|

Press-working of sheet metal

|

Downstroke press

|

|

Hydraulic design principle

|

Solenoid cartridge valve with adjustable pressure

|

|

Dimensions

|

L1.65m*W0.8m*H2.1m

|

Machine Features

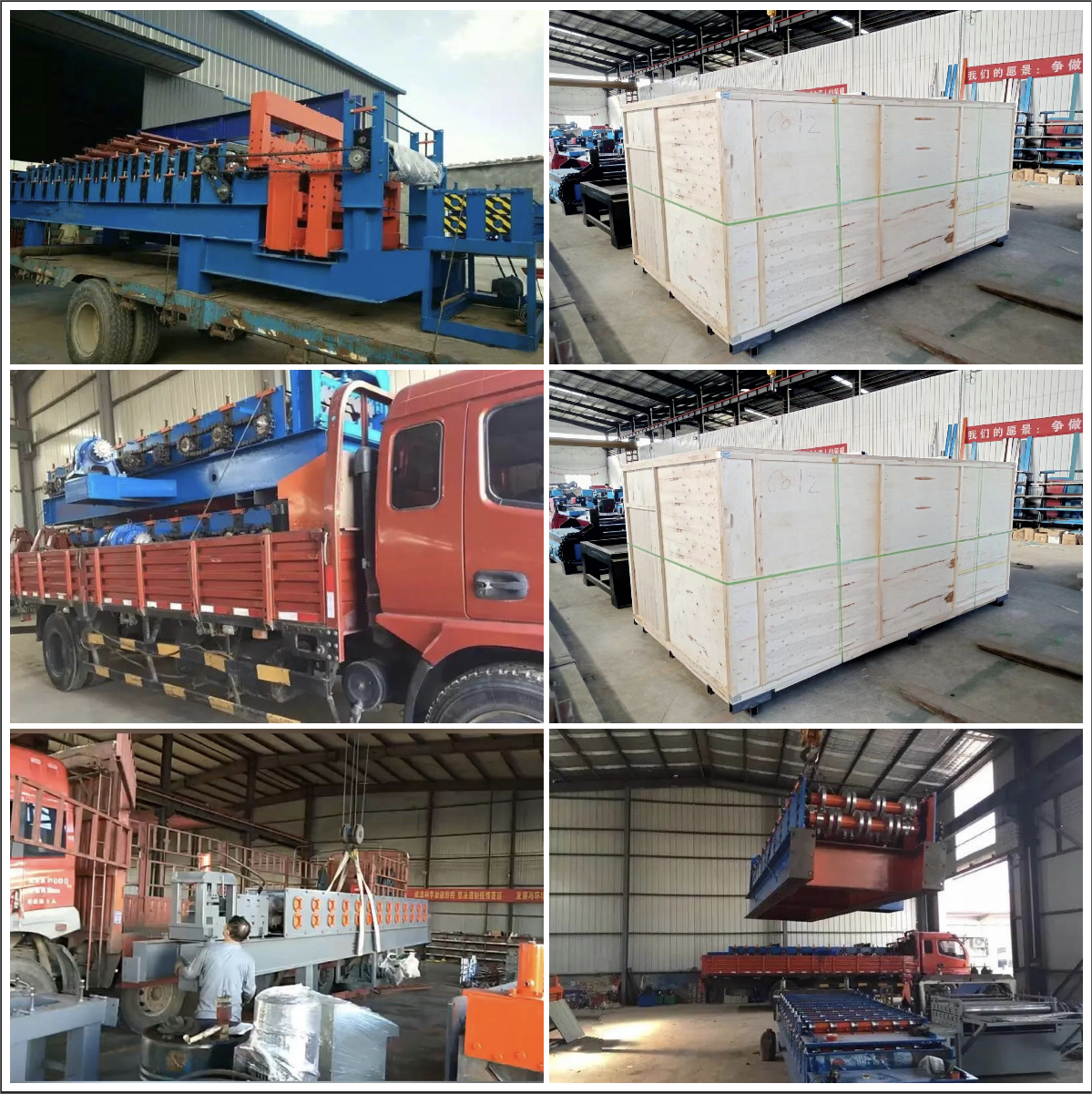

Packaging Type Of Bag

Machine Function

Machine Option

Machine Application

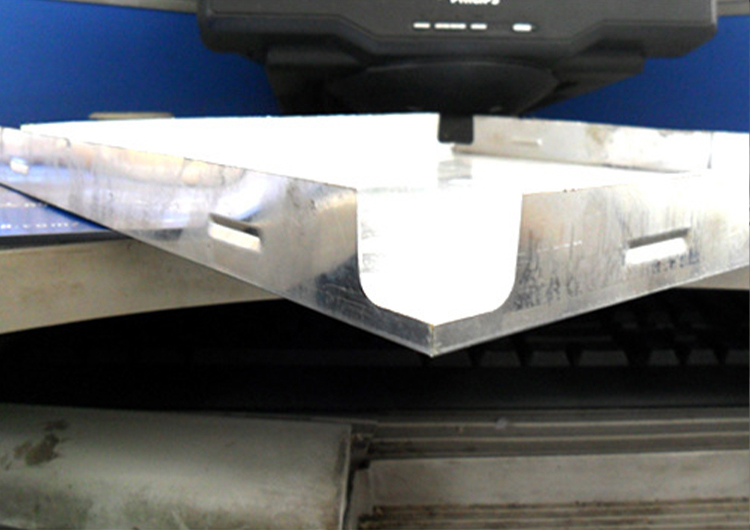

Integrated ceiling equipment is a machine that specializes in the production and processing of aluminum gussets. It is collectively referred to as integrated ceiling equipment, and can also be called integrated ceiling machines, integrated ceiling machinery, and integrated ceiling hydraulic presses. The machines are universal and can be assembled with primary forming molds or secondary forming molds. The machine is also divided into different table sizes, and the molds that can be loaded with different sizes are also different.

Related Products

CONTACT US

Featured Categories

Contact Us

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

© Copyright – 2003-2023 : Zhengzhou Howann Machinery Co., Ltd All Rights Reserved.