Products Categories

Feature Products

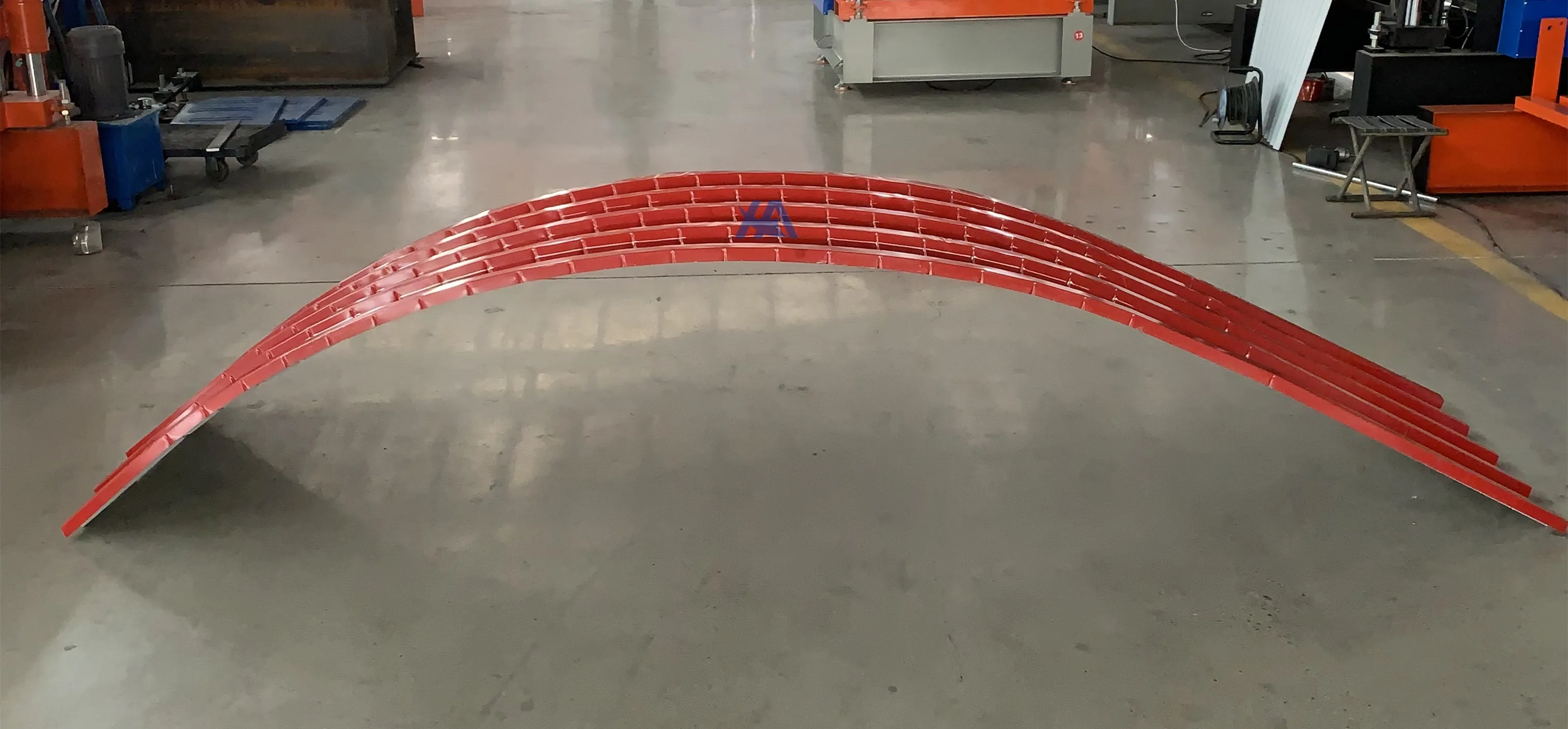

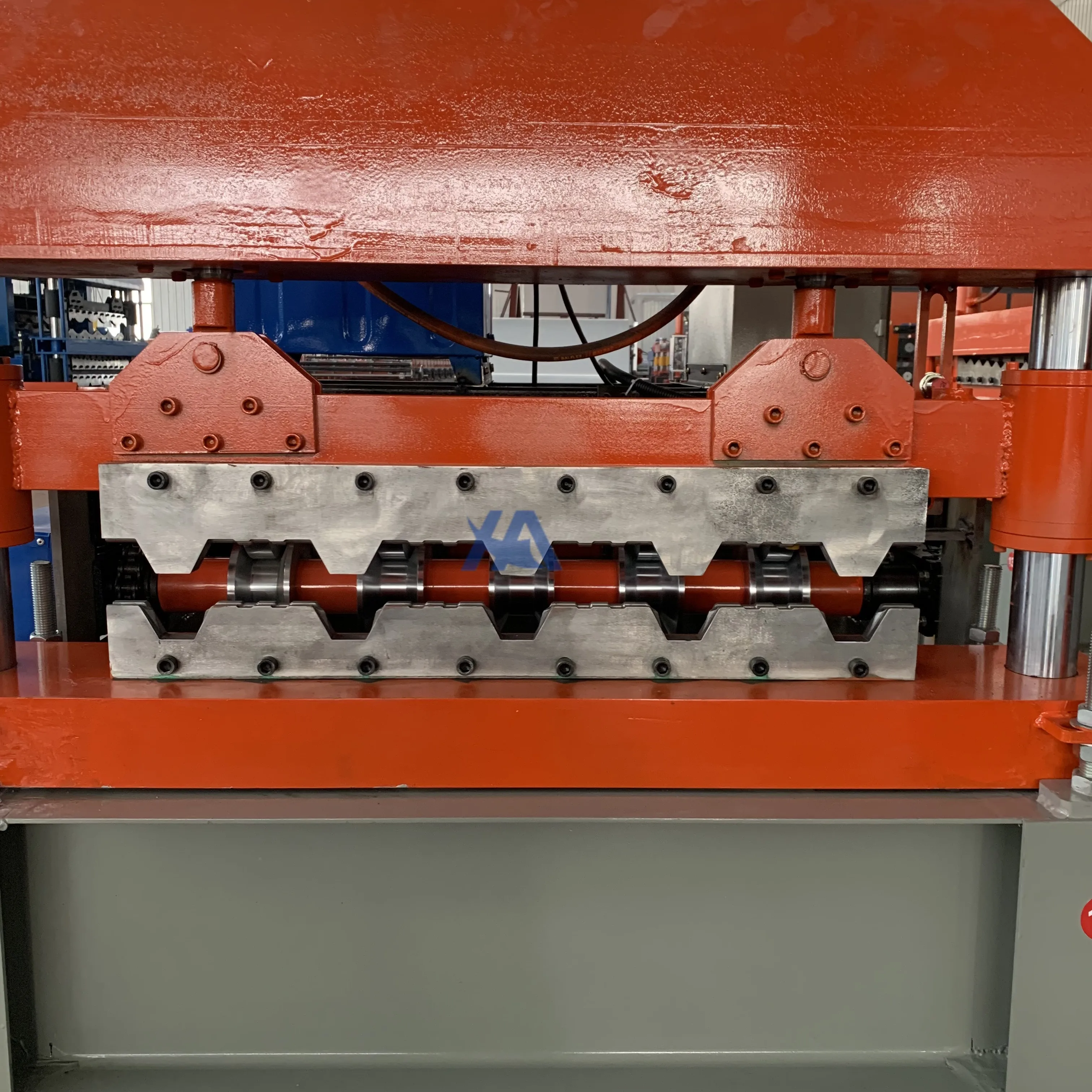

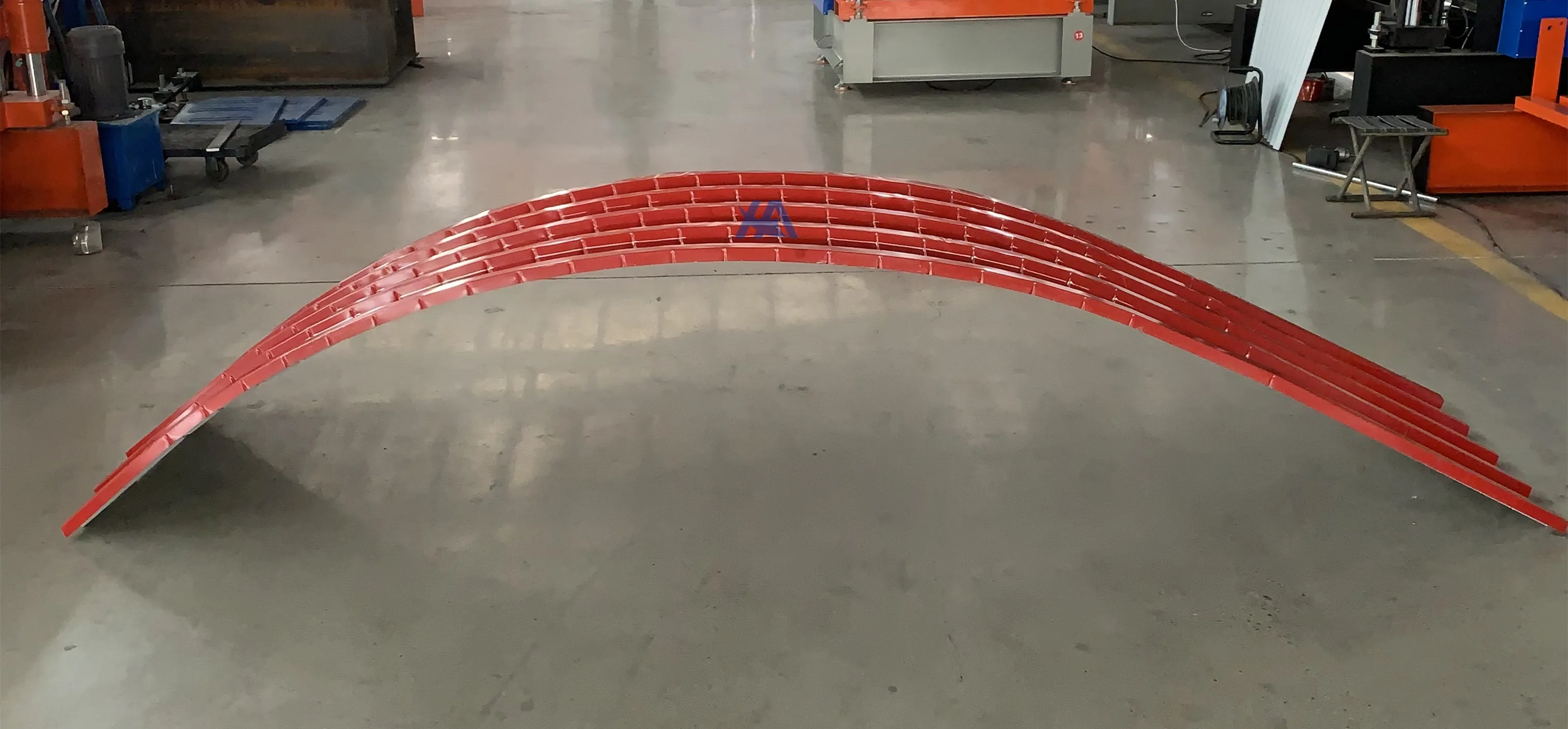

Arch Crimping Curve Roofing Forming Machine

A crimping and curving machine is a tool used to bend or shape metal objects. It is usually used to create intricate shapes and curves in metal. The machine is typically hand-operated and uses a press-like action to apply pressure to the metal object, bending it into the desired shape. It is also used to crimp and attach objects together, such as wire mesh or sheet metal. Crimping machines can be used to create a variety of shapes and curves, from simple bends and curves to intricate curves and designs.

Machine Video

Machine Specification

|

Suitable to process

|

Color steel plate, galvanized sheet, aluminum coils and etc

|

|||

|

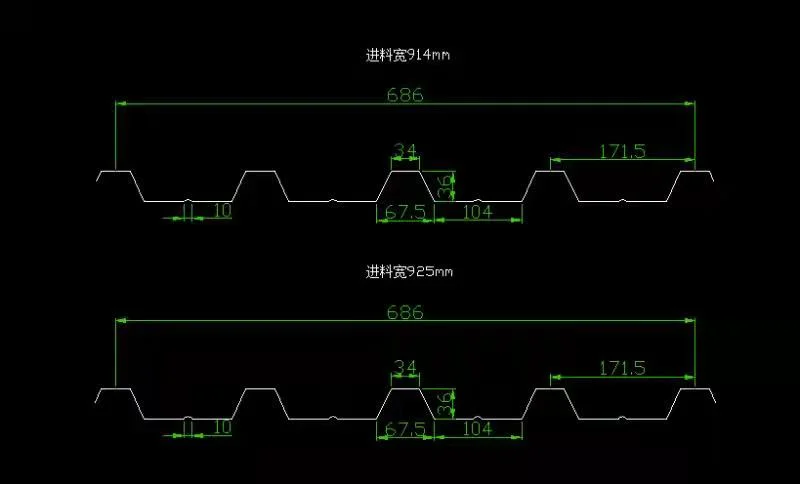

Width of the feeding material

|

925 mm or as your need

|

|||

|

Productivity

|

8-10m/min

|

|||

|

Weight

|

About 1T

|

|||

|

Demensions

|

1.6*1.5*1.6m(L*W*H)

|

|||

|

Cutting material

|

Cr 12 Mov

|

|||

|

Thickness of feeding material

|

0.3-0.8mm

|

|||

|

Rollers’ material

|

45#steel

|

|||

|

Voltage

|

380 V 50Hz, 3 Phase or as your need

|

|||

|

Motor power

|

4+3kw

|

|||

|

Custom

|

According to your need.

|

|||

Machine Features

Packaging Type Of Bag

Machine Function

Feeding Rack

Usage: The receiving rack is 1m-1.2m wide (equipment can be purchased)

Machine Option

Machine Application

Related Products

CONTACT US

Featured Categories

Contact Us

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

© Copyright – 2003-2023 : Zhengzhou Howann Machinery Co., Ltd All Rights Reserved.