Products Categories

Feature Products

Automatic Flexible Adjustable Flat Iron Pipe Clamp Making Machine

The equipment for straightening, conveying, punching, typing, and bending forming of flat iron or stainless steel raw materials can be just straightening, conveying, cutting, forming, or typing and then bending. The production of different shapes of accessories can be operated by only one person, saving labor costs; CNC operation, without manual calculation, has higher accuracy; one-time molding, higher production efficiency; production of different types of hoops can only be adjusted by parameters, It is more convenient to use.

Machine Video

Machine Specification

|

Item

|

Data

|

|

Suitable carbon steel wire gauge

|

Φ0.6~2.5mm (3mm)

|

|

Suitable steel strip width

|

40mm

|

|

Suitable steel strip thickness

|

0.3~1.5mm

|

|

Max. feeding length per stroke

|

200mm (250mm)

|

|

Feeding precision

|

+/-0.003mm

|

|

Punching force of punching head

|

10 ton

|

|

Total motor power

|

7kW

|

|

Production speed

|

20~30 pcs/min

|

|

Machine dimension

|

About 2000 x 1000 x 2000mm

|

|

Machine weight

|

About 2000kg

|

Machine Features

1.Saving material: conventional pressing machine needs wider strips for automatic production; This machine uses exact wide strip for production.

2.High efficiency: capability of one automatic machine is equal to that of seven pressing machines at least. And so energy consumption is also saved.

3.More stable processing quality because of continuous processing automatically.

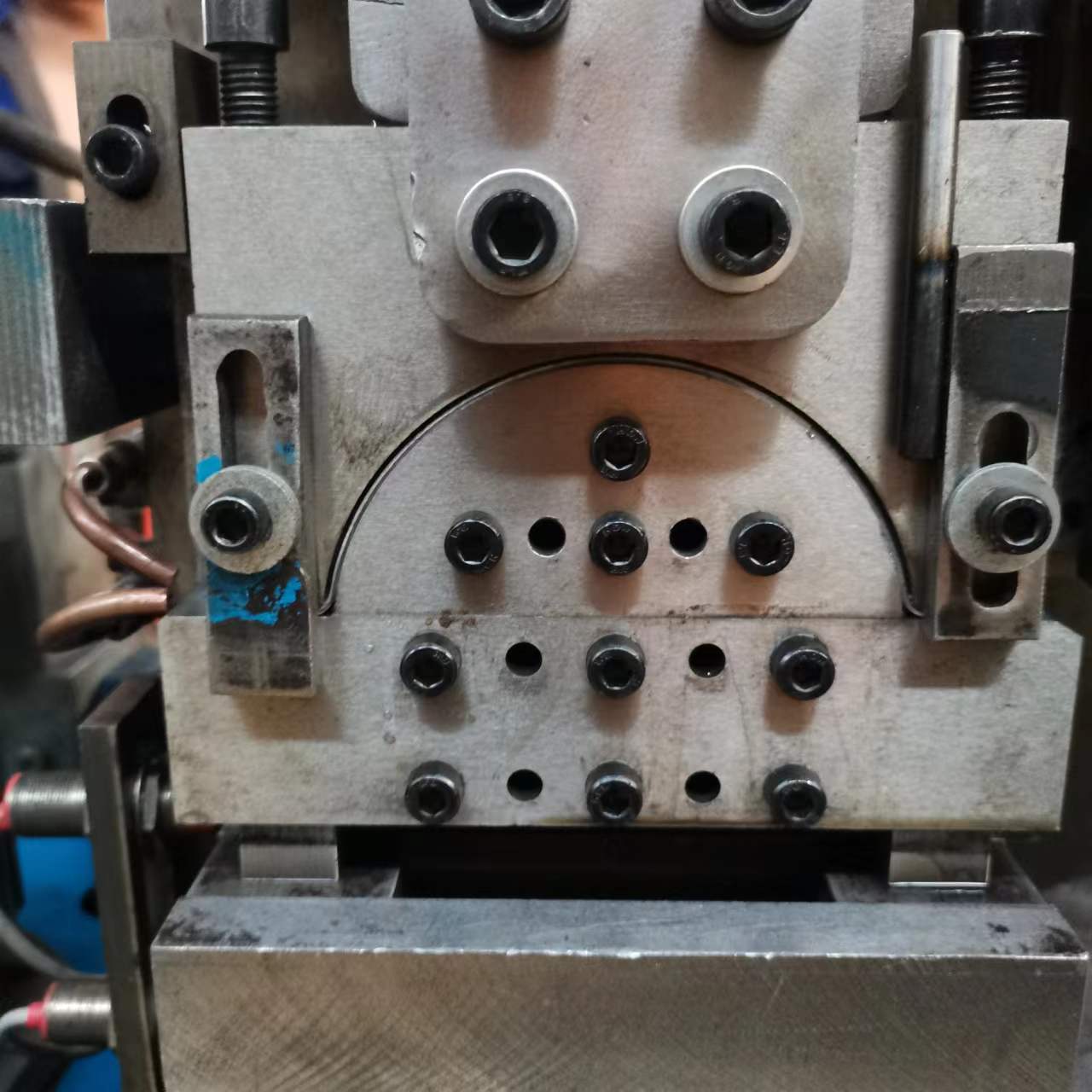

4.Cheaper mould cost: one combined mould can replace several moulds on several pressing machines; Mould frames are also saved.

5.Automatic lubricating, less wearing, suitable for mass production.

Packaging Type Of Bag

Wooden package

Machine Function

The equipment for straightening, conveying, punching, typing, and bending forming of flat iron or stainless steel raw materials can be just straightening, conveying, cutting, forming, or typing and then bending.

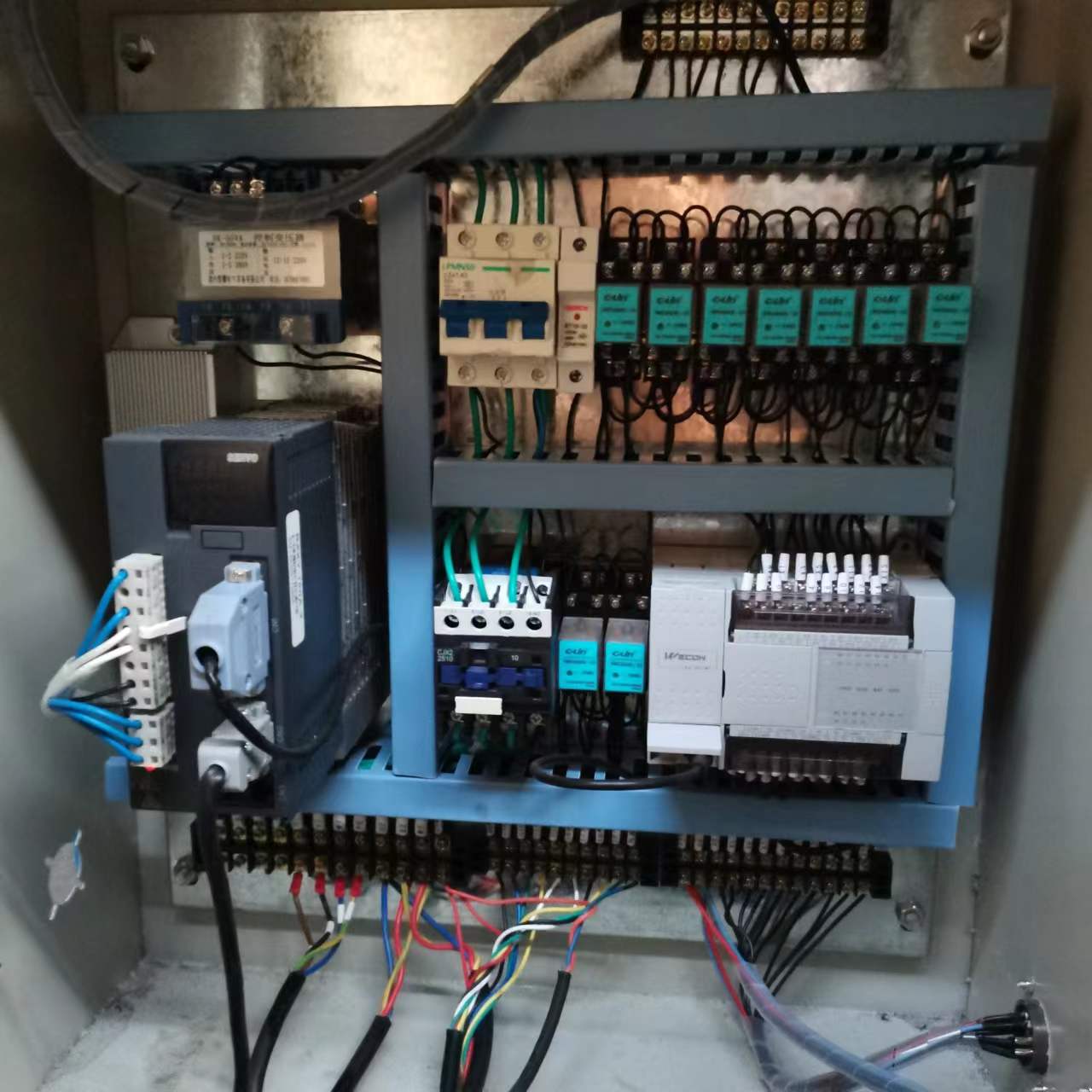

Machine Option

Electric Control Box

Machine Application

The equipment for straightening, conveying, punching, typing, and bending forming of flat iron or stainless steel raw materials can be just straightening, conveying, cutting, forming, or typing and then bending. The production of different shapes of accessories can be operated by only one person, saving labor costs; CNC operation, without manual calculation, has higher accuracy; one-time molding, higher production efficiency; production of different types of hoops can only be adjusted by parameters, It is more convenient to use.

Related Products

CONTACT US

Featured Categories

Contact Us

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

© Copyright – 2003-2023 : Zhengzhou Howann Machinery Co., Ltd All Rights Reserved.