Products Categories

Feature Products

Automatic Hydraulic Pipe Clip Forming Machine Metal Hose Clamp Making Machine Flat Iron Hoop Punching Machine

The equipment for straightening, conveying, punching, typing, and bending forming of flat iron or stainless steel raw materials can be just straightening, conveying, cutting, forming, or typing and then bending. The production of different shapes of accessories can be operated by only one person, saving labor costs; CNC operation, without manual calculation, has higher accuracy; one-time molding, higher production efficiency; production of different types of hoops can only be adjusted by parameters, It is more convenient to use.

Machine Video

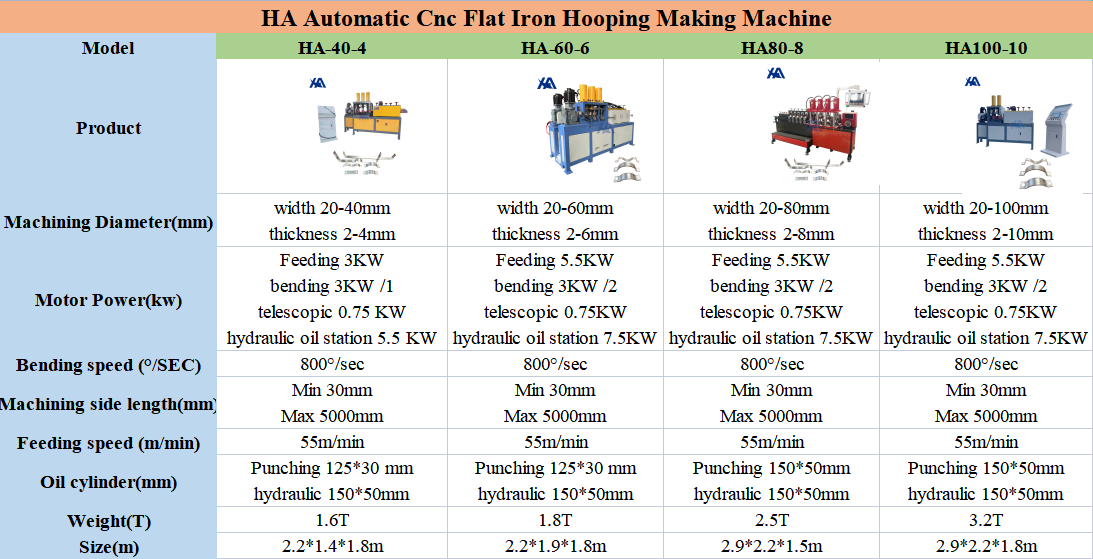

Machine Specification

| Basic Configuration | 1. One set of pressure system (7.5kw)

2. One main control box 3. A set of CNC system (Delixi Electric) 4. Two hydraulic cylinders 6. One loading rack 7. Solenoid valve 2 groups 8. A bending servo motor (5.5kw), a feeding servo motor (5.5kw) |

|||

| Production speed | 1. According to different products and different processes, this machine adopts PLC frequency conversion speed control.

2. The production speed is calculated according to the shape size, bending times and punching times. 3. Adaptable to product thickness 2-5mm, adaptable to product material width 50mm. |

|||

| Operation form | Automatic (button + touch screen) | |||

| Rack load capacity | Within 3T | |||

Machine Features

Howann flat iron pipe clamping making machine—The equipment for straightening, conveying, punching, typing, and bending forming of flat iron or stainless steel raw materials can be just straightening, conveying, cutting, forming, or typing and then bending. The production of different shapes of accessories can be operated by only one person, saving labor costs; CNC operation, without manual calculation, has higher accuracy; one-time molding, higher production efficiency; production of different types of hoops can only be adjusted by parameters, It is more convenient to use.

Packaging Type Of Bag

Wooden package

Machine Function

The equipment for straightening, conveying, punching, typing, and bending forming of flat iron or stainless steel raw materials can be just straightening, conveying, cutting, forming, or typing and then bending.

Machine Option

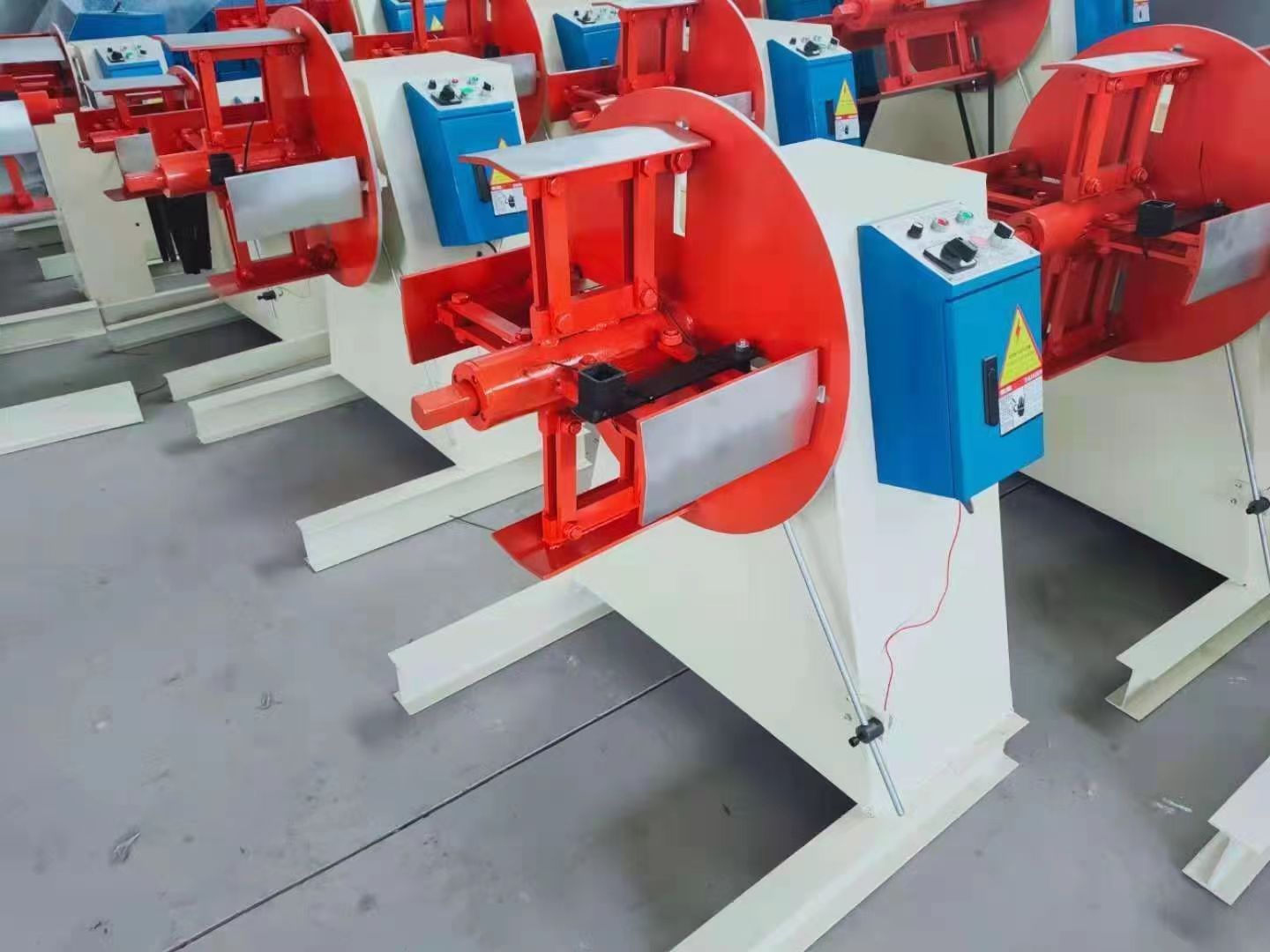

Rack

The main realization of raw material supply,raw materials wound in a large drum,with the rotation of the drum, continuous feed to the host.

Feeding Device

Be responsible for sending the hoop material on the material rack to the designated position of the main machine to realize the work of the main machine.

Bending Device

The material rack will clamp the raw materials,type,punch,cut and form the finished products in turn.

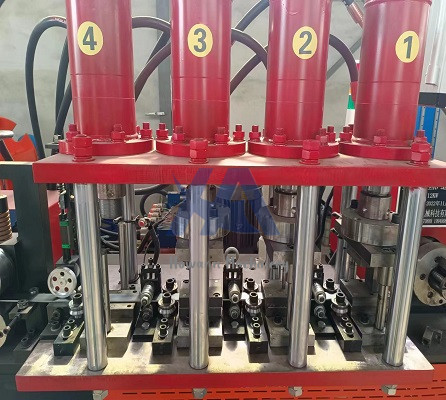

Hydrocylinder

For punching,cut off,can be customized to customer request

Final product

We can process thickness up to 10mm materials. And there is no need the change the mold by hands, just adjust the setting on control box then to realize the various shapes.

The final Product is in good quality and accuracy.

Machine Application

The equipment for straightening, conveying, punching, typing, and bending forming of flat iron or stainless steel raw materials can be just straightening, conveying, cutting, forming, or typing and then bending. The production of different shapes of accessories can be operated by only one person, saving labor costs; CNC operation, without manual calculation, has higher accuracy; one-time molding, higher production efficiency; production of different types of hoops can only be adjusted by parameters, It is more convenient to use.

Related Products

CONTACT US

Featured Categories

Contact Us

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

© Copyright – 2003-2023 : Zhengzhou Howann Machinery Co., Ltd All Rights Reserved.