Products Categories

Feature Products

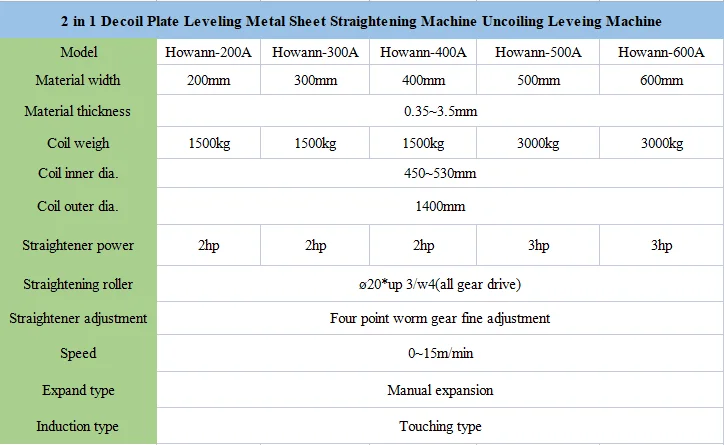

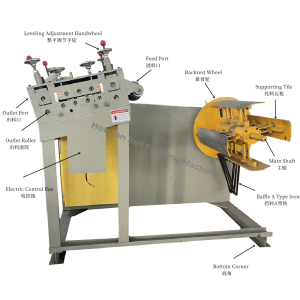

Coils Decoiler Leveler Machine For Steel Strips Automatic 2 in 1 Coil Uncoiling Straightening Straightener

The straightener is drive by universal joint, full gear drive, avoid the material damage caused by the passive rotation of the upper rollers effectively.

The straightening roller with dial indicator, can find leveling point quickly.

Machine Video

Machine Specification

Machine Features

Straightener head

Adopt parallel roller design, 3 up / 4 down, totally 7 rollers.

Adopt four point fine adjustment is adopted, which is more suitable for processing high-precision products. Adopt four point independent pressure to adjust the pressure of feeding roller for entrance and exit, which can prevent material deviation and deformation effectively.

The supporting roller adopts the galvanizing roller without power, the material is one body formed, the surface is scratch-resistant and wear-resistant, use the mechanical bearing, rotating flexible and durable.

Handwheel made of cast iron, surface is electroplated. It is the most traditional handwheel.

The transmission part is protected by protective cover on both sides, equipped with observation window for easy viewing.

Packaging Type Of Bag

Machine Function

Drive Gear

Gear processing includes the following processes: gear blank processing – gear surface machining – heat treatment – gear surface fine grinding. Rough parts are mainly forging parts. Through normalizing treatment, improve the machining to facilitate cutting. According to the gear design drawings, rough machining, and then semi-finishing processing, turning, rolling, gear shaping, to

make the gear basically formed. After the heat treatment to improve the mechanical properties. According to the design requirements of the drawings, finally do the finishing, finishing the benchmark, finishing the tooth profile. After all above treatments, our gear grade can reach to grade 6, with high wear resistance, high strength, long using life.

Frame Part

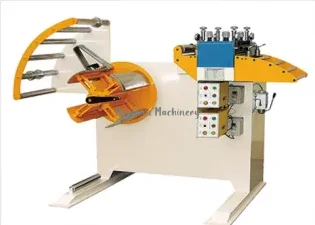

Decoiler adopt cantilever beam design, all plates of the decoiler are cut by laser plasma with high precision.

All parts are processed by numerical control and CNC, with good interchangeability.

The overall structure is simple, it is convenient for general technical workers to assemble and replace, can greatly reduces the maintenance cost

Straightening roller

The straightening rollers are made of solid bearing steel, thickening plating treatment after medium frequency, surface hardness is not less than HRC58, to ensure material durability.

2. Adopt GCr15 forging round steel, after preheating treatment (spheroidal annealing), then turning, milling, intermediate frequency treatment, rough grinding and cold stabilization, then fine grinding, finally electroplating. Maximized guarantee the accuracy, concentricity, finish and hardness, and extended the using life of the rollers.

Machine Option

Machine Application

The automatic cut to length line is commonly used in the metal working industry to produce a wide variety of products such asautomotive parts, appliances, building materials, and steel furniture. The machine uses a combination of cuting bladesleveling rollers, and conveyor belts to perform the cutting and shaping process.

Related Products

CONTACT US

Featured Categories

Contact Us

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

© Copyright – 2003-2023 : Zhengzhou Howann Machinery Co., Ltd All Rights Reserved.