Usage: Continuously provide power to the equipment to keep the equipment running continuously.

Products Categories

Feature Products

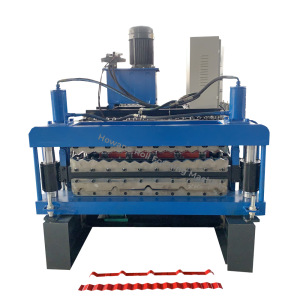

Double Layer Roll Forming Machine for Saving Budget and Space

Double layer roll forming machine is a machine composed of unwinding, forming, and post-forming cutting. Its color plate has a flat and beautiful appearance, uniform paint patterns, high strength, and durability. It is widely used in industrial civil buildings, such as factory buildings, warehouses, stadiums, exhibition pavilions, theaters and other rooms and walls.

Machine Video

Machine Specification

|

Voltage

|

380v

|

|

Dimension(L*W*H)

|

6000mm*1400mm*1300mm

|

|

Weight

|

3000kg

|

|

Rolling thinckness

|

0.2-0.8mm

|

|

Max.speed

|

15m/min

|

|

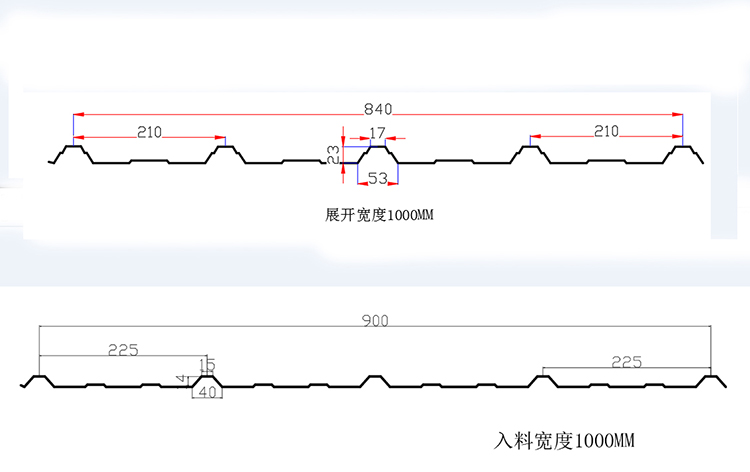

Max.loading width

|

1200mm/1000mm or according to your demands

|

|

Machine frame

|

300H steel welded

|

|

Middle plate thickness

|

14mm

|

|

Spacer

|

seamless steel tube processing

|

|

Roller material

|

45# steel forged

|

|

Shaft material

|

70mm,45# steel forged

|

|

Motor power

|

3kw

|

|

Cuter material

|

Cr12

|

Machine Features

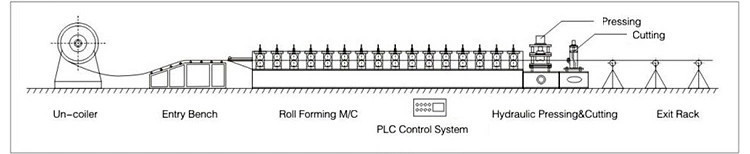

The Working Flow

Manual uncoiler—feeding device—rolling form—speed, length, pieces set by PLC—hydraulic mold post cutting—collection table

Packaging Type Of Bag

Machine Function

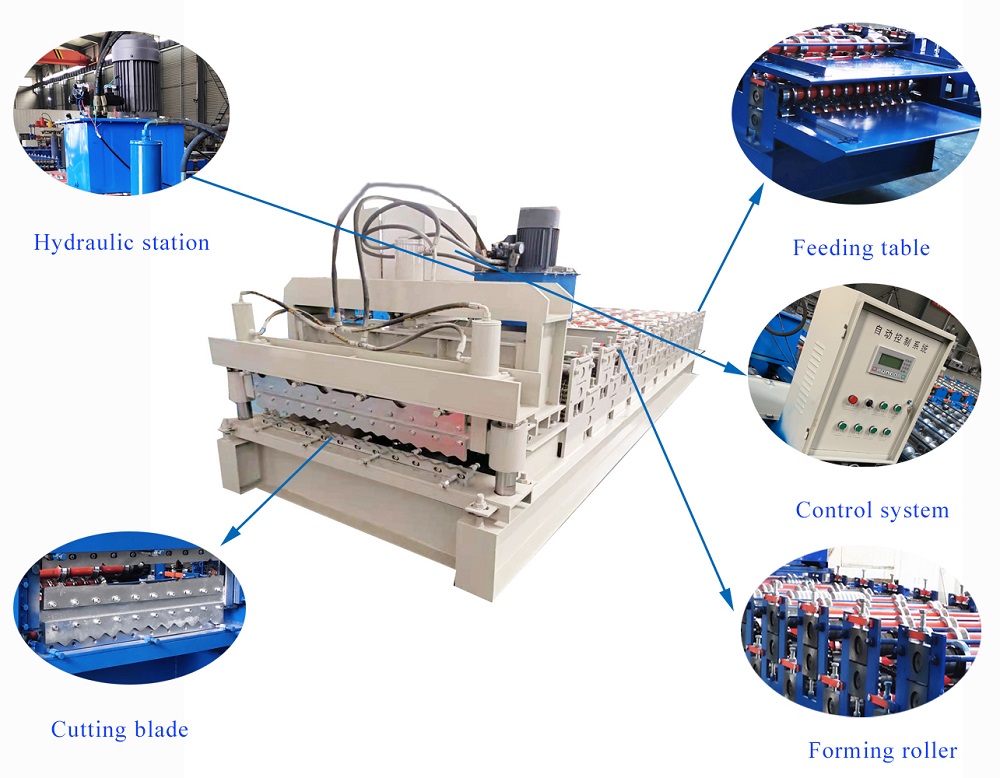

Hydraulic Uncoiler

Hydraulic Power Station

Usage: Continuously provide power to the equipment to keep the equipment running continuously.

Usage: It can promote the automatic production of machinery and save manpower and material resources to a great extent.

Usage: It is made of 45# steel, polished and heat treated. Processed products are not easy to deform.

Usage: It adopts the Motor drive and automatic location to decide the dimension and cut the target products.

Usage: It adopts welded steel and supported roller to transmit the products,which is used to collect the finished products.

Machine Option

Machine Application

Related Products

CONTACT US

Featured Categories

Contact Us

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

© Copyright – 2003-2023 : Zhengzhou Howann Machinery Co., Ltd All Rights Reserved.