Products Categories

Feature Products

Downspout Gutter Round Or Square Pipe Forming Machines

Gutter cold roll forming machine is composed of uncoiler, the feed leading table, the main machine, the formation cutting device, hydraulic system, control system and the product bracket.

Machine Video

Machine Specification

|

Applicable Industries

|

Building Material Shops, Manufacturing Plant, Construction works

|

|

Product Name

|

gutter Roll Forming Machine

|

|

Frame Materials

|

350H steel

|

|

Diameter

|

80mm

|

|

Forming roller

|

16row

|

|

Forming Shaft

|

Material 45# quenched and tempered

|

|

Max.speed

|

15m/min

|

|

Effective with

|

80-300mm

|

|

Pressing width

|

1000mm

|

|

Cutting System

|

Hydraulic Cutting

|

|

Main Engine power

|

22 KW with cycloidal reducer

|

|

Electric tension

|

380V 50 Hz 3 Phase or as your requirements

|

|

Hydraulic oil

|

40# hydraulic oil

|

|

Material of cutting table

|

Cr 12 mould steel with quenched treatment

|

Machine Features

1.Saving material: conventional pressing machine needs wider strips for automatic production; This machine uses exact wide strip for production.

2.High efficiency: capability of one automatic machine is equal to that of seven pressing machines at least. And so energy consumption is also saved.

3.More stable processing quality because of continuous processing automatically.

4.Cheaper mould cost: one combined mould can replace several moulds on several pressing machines; Mould frames are also saved.

5.Automatic lubricating, less wearing, suitable for mass production.

Packaging Type Of Bag

Machine Function

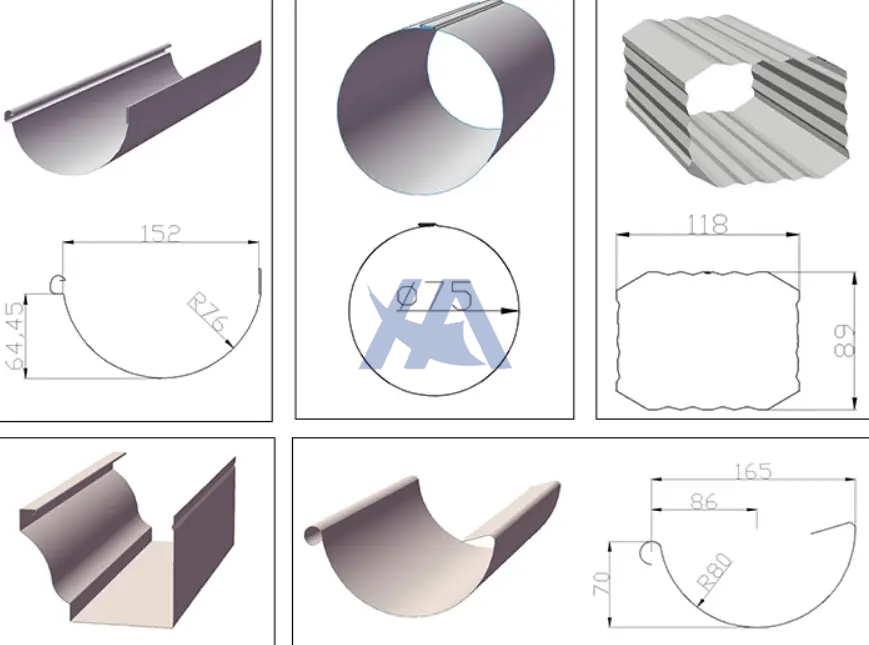

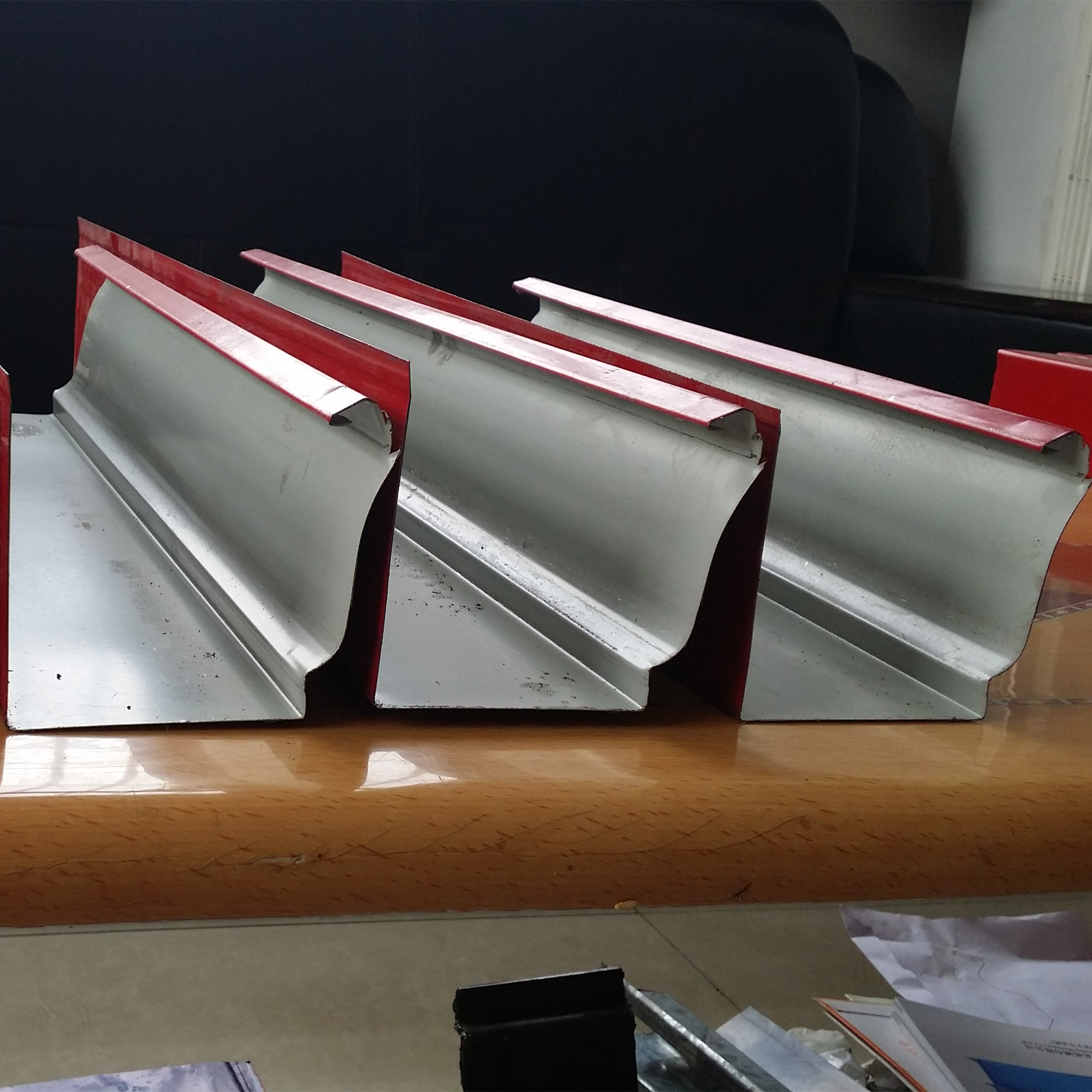

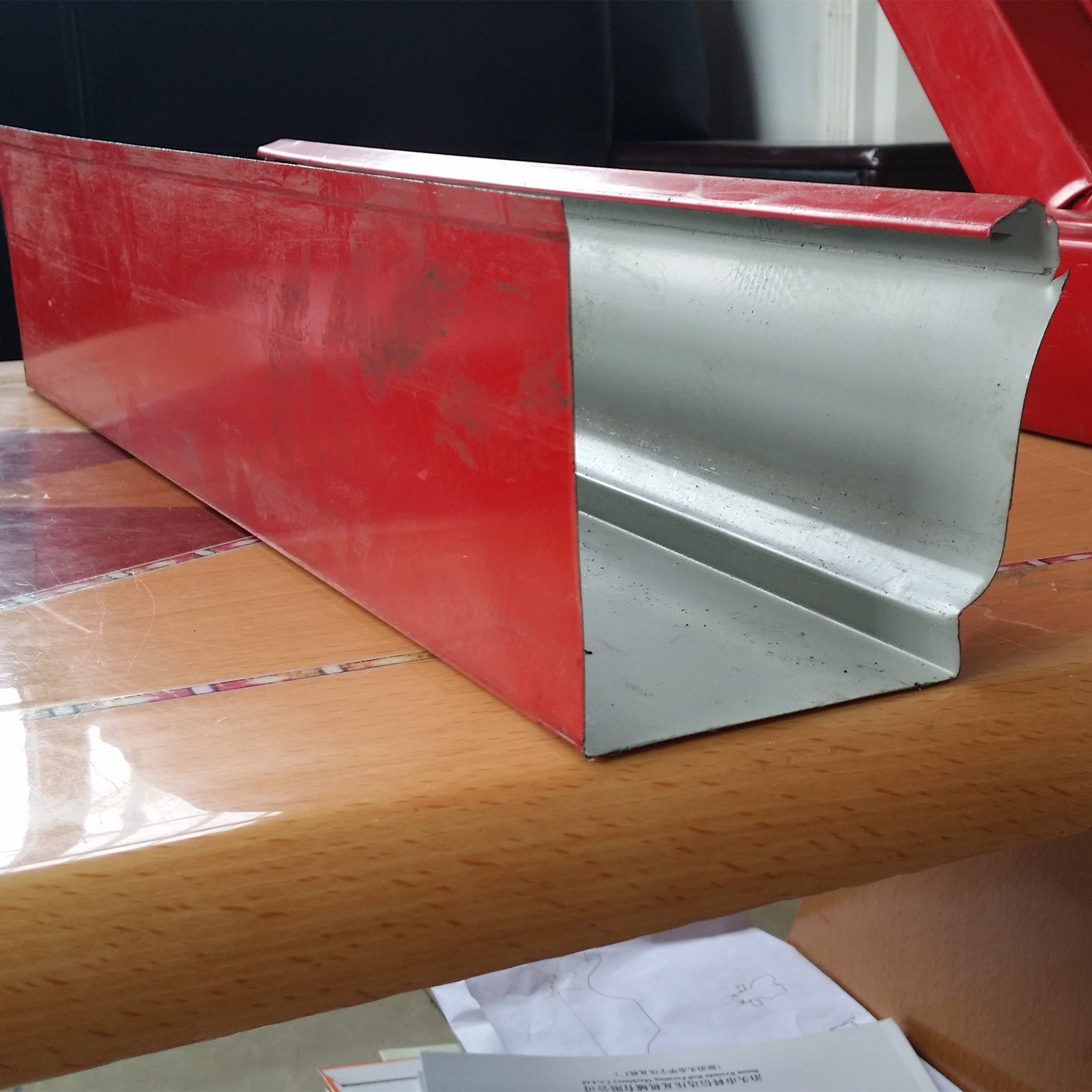

Gutter roll forming machine is suitable for companies who work on rainwater goods system. Machinable thickness of gutter could be 0.4mm-0.6mm or as you request with raw material: Aluminum, Galvanized steel, Painted steel, Galvalume and Cooper etc. We could make machine solution for Quad Gutter, Quarter Round Gutter, C-Square Gutter, Hi-Square Gutter, Lo-Square Gutter, VC Gutter, VF Gutter, VFC Gutter, VFM Gutter, VT Gutter, OG Gutter, OG Big One Gutter, S Gutter, Half Round Gutter, Smoothline Gutter, Round Flo Gutter or according to your profile drawing.

Machine Option

Gutter cold roll forming machine can bend the roll formed pipe, and let the drainpipe and the bending connect to be the whole.The product after roll forming has long working time than the tranditional ppc pipe, and not aging. It can make the project more integrate, and help to enhance the image of the all project.

Machine Application

Related Products

CONTACT US

Featured Categories

Contact Us

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

© Copyright – 2003-2023 : Zhengzhou Howann Machinery Co., Ltd All Rights Reserved.