Products Categories

Feature Products

Electric Manual Plate Bending Machine Price Manual Sheet Metal Bending Machine

Simple bending machine :

Machine Video

Machine Specification

|

4000mm Width Hydraulic Bending Machine Best Price Metal Sheet Bender MachineryNo.

|

4000mm Width Hydraulic Bending Machine Best Price Metal Sheet Bender Machinery

|

|

Suitable to process

|

(Prepainted)galvanized steel plate

|

|

Processing thickness

|

Max 2mm or according to customer’s need

|

|

Sheet max width

|

2.5 Meters/4Meters/6Meters

|

|

Electric tension

|

380V 3phase 50HZ or as your request

|

|

Angle type

|

4 Kinds

|

|

Weight

|

About 1.25T

|

|

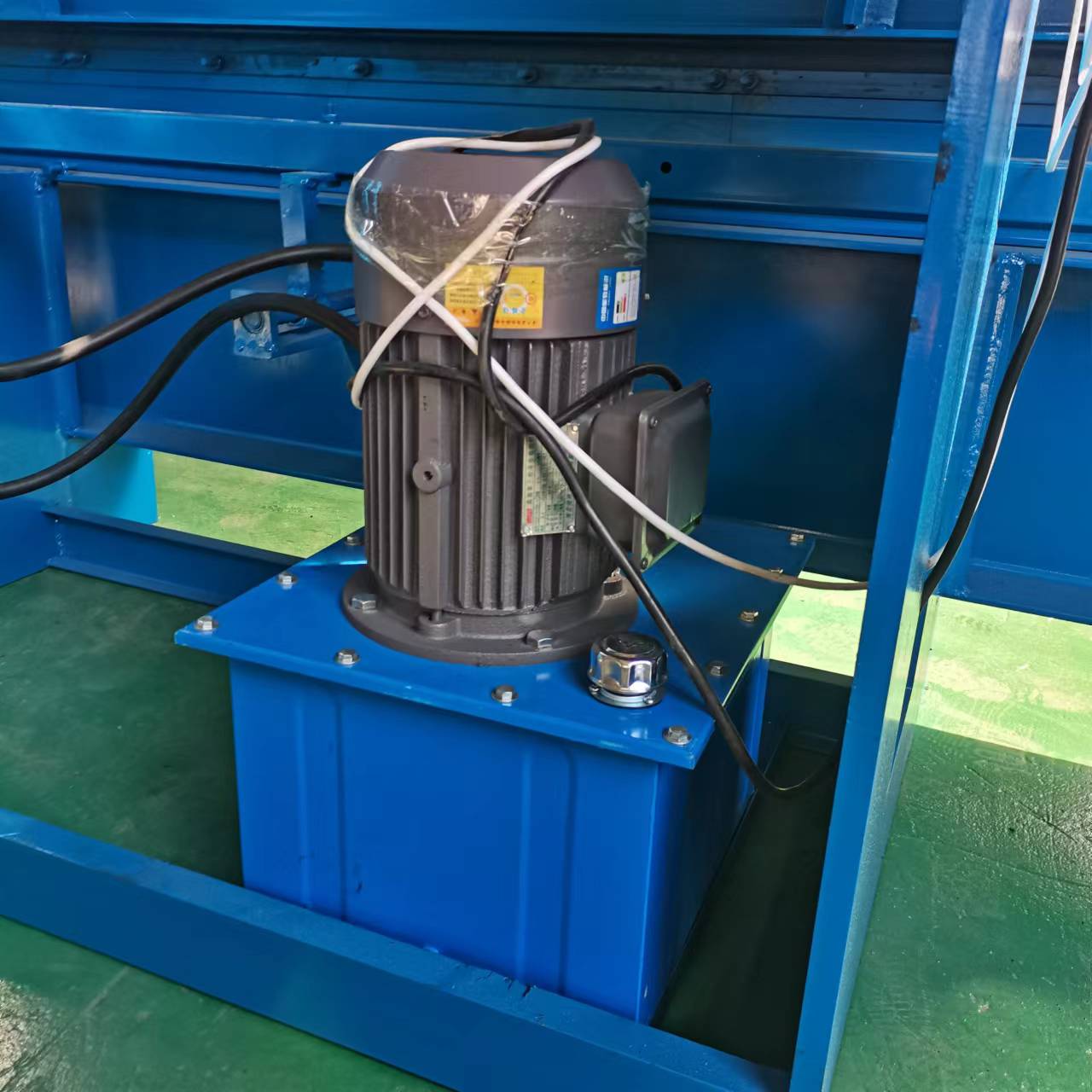

Hydraulic motor

|

3Kw

|

|

Yield Strength

|

G350

|

|

Hydraulic Cylinder Quantity

|

2/3 units

|

|

Bending Mold

|

Cr12

|

|

Bending Angle

|

90°,120°,135°

|

|

Electrical Control Box

|

Manual button

|

|

Voltage

|

220V/240V/380V/415V/440V

|

|

Size

|

4050*1000*1200mm

|

Machine Features

Features for folding machine:

1. Adopt all-steel welded structure, with sufficient strength and rigidity;

Packaging Type Of Bag

Machine Function

Instruction for Bending Machine:

The bending machine is a machine that can bend thin plates. Its structure mainly includes a bracket, a working table and a

clamping plate.

Machine Option

Machine Application

Equipment frame structure

Cylinder

Hydraulic pump station:

Electric control box

Related Products

CONTACT US

Featured Categories

Contact Us

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

© Copyright – 2003-2023 : Zhengzhou Howann Machinery Co., Ltd All Rights Reserved.