Small error good operation.

Products Categories

Feature Products

Hot Sale Hat Shape Light Keel Channel Drywall Purlin Roll Forming Making Machine

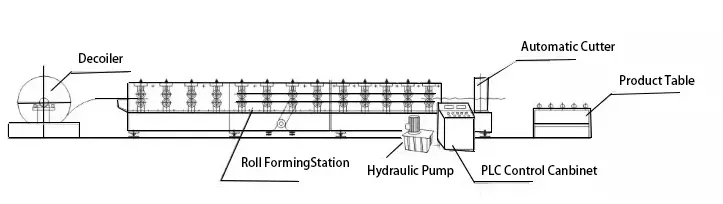

The C channel forming machine is manufactured with advanced technologies.Not only does this series have a beautiful design, but it is also greatly economical and practical. This C purlin forming machine series uses the industrial-grade computer motion control system to assist its intelligent digital operation interface. With the superior humanized design, our C channel roll forming machine is easy to use.

Machine Video

Machine Specification

|

Product name

|

4 in 1 Purlin Roll Forming Machine

|

|||

|

Frame materials

|

350H steel

|

|||

|

Diameter

|

80mm

|

|||

|

Forming roller

|

16row

|

|||

|

Forming shaft

|

Material 45# quenched and tempered

|

|||

|

Max.speed

|

15m/min

|

|||

|

Feeding width

|

1000mm

|

|||

|

Cutting system

|

Hydraulic Cutting

|

|||

|

Main engine power

|

22 KW with cycloidal reducer

|

|||

|

Voltage

|

380V 50 Hz 3 Phase or as your requirements

|

|||

|

Hydraulic oil

|

40# hydraulic oil

|

|||

|

Material of cutting table

|

Cr 12 mould steel with quenched treatment

|

|||

|

Applicable industries

|

Building Material Shops, Manufacturing Plant, Construction works

|

|||

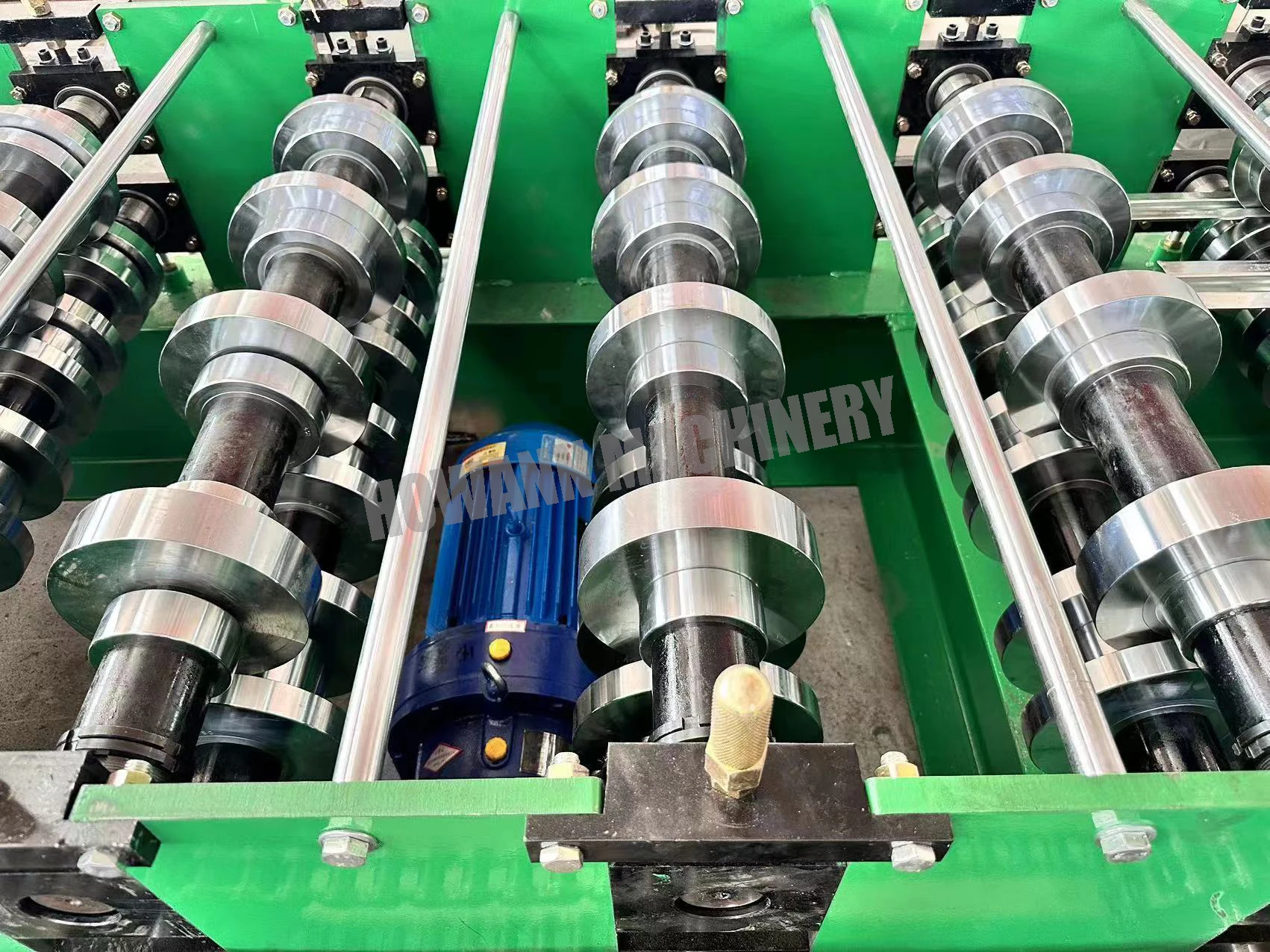

Machine Features

Packaging Type Of Bag

Machine Function

Small error good operation.

Material of the roller: High grade No.45 forged steel

Roller station: 12-14 rows

Machine Option

3 in 1 c channel machine | multiple c channel machine | C u channel roll forming machine Multiple C channel machine popular sell in many countries, common thickness between 0.3-0.6 mm, Common speed 10-20 m/min, with servo motor speed can max reach to 30-50 m/min, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc

Machine Application

Related Products

CONTACT US

Featured Categories

Contact Us

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

© Copyright – 2003-2023 : Zhengzhou Howann Machinery Co., Ltd All Rights Reserved.