Small error good operation.

Products Categories

Feature Products

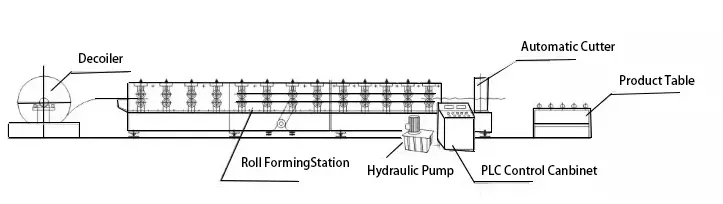

Factory Direct Snap Lock Standing Seam Roll Forming Machine

Manufactured directly in our ISO-certified facility, this roll forming machine produces structural roof panels with an accuracy of ±0.4 mm (compliant with ASME Y14.5 aerospace-grade standards). The automated PLC-controlled machine boasts a production speed of up to 22 m/min and can process galvanized/aluminum/zinc alloys with thicknesses ranging from 0.4 to 1.2 mm.

Machine Video

Machine Specification

|

Product name

|

Standing Seam Roll Forming Machine

|

|

Main motor power

|

4kW/5.5KW/7.5KW or as actual demands

|

|

Hydraulic motor power

|

3kW/4KW.5.5KW or as actual demands

|

|

Voltage

|

380V/ 3 phase/ 50 Hz (or as your requirements)

|

|

Control system

|

Automatic PLC control system

|

|

Feeding thickness

|

0.4-0.5mm

|

|

Cutting method

|

Hydraulic cutting

|

Machine Features

Packaging Type Of Bag

Machine Function

Small error good operation.

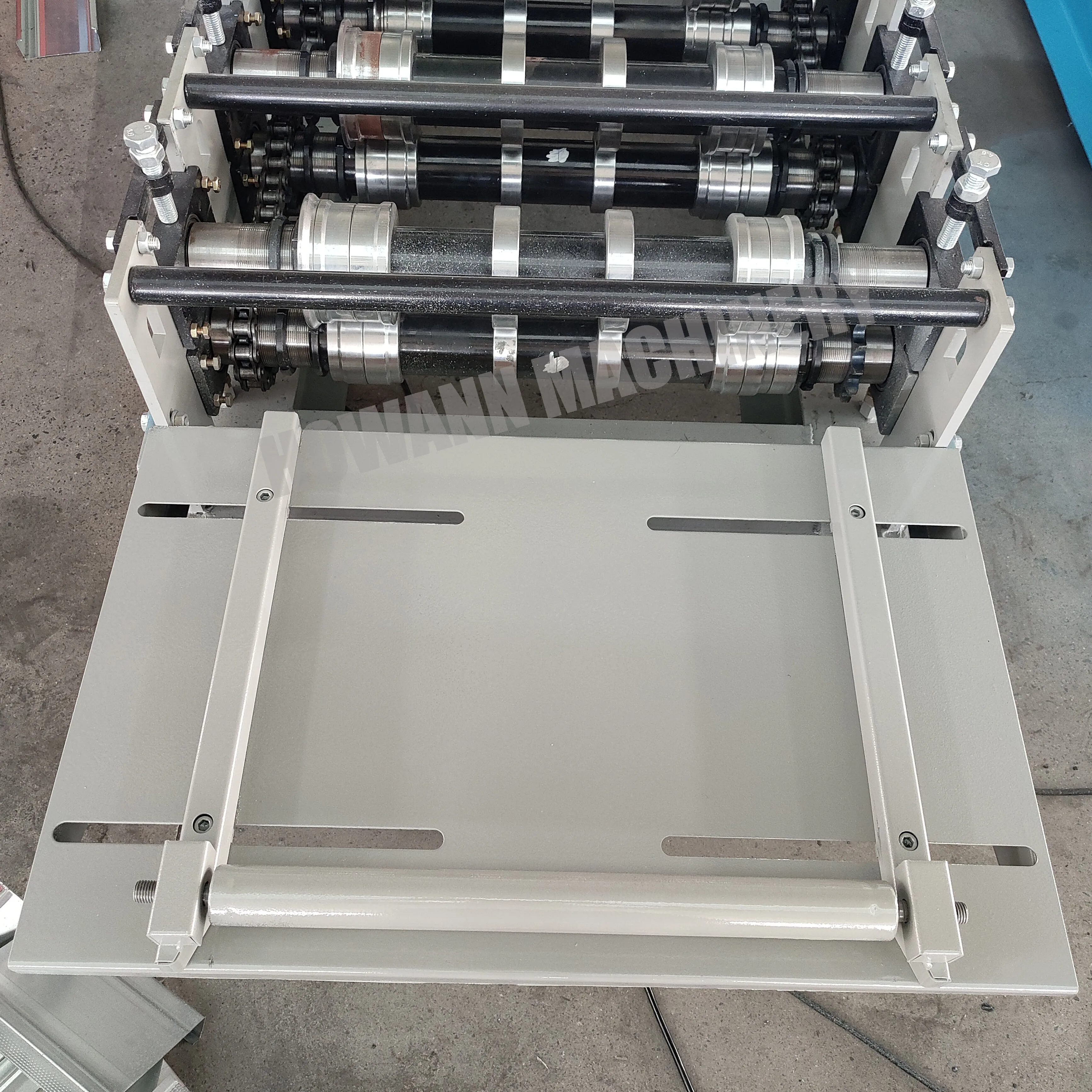

Material of the roller: High grade No.45 forged steel

Roller station: 12-14 rows

Machine Option

Machine Application

Related Products

CONTACT US

Featured Categories

Contact Us

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

© Copyright – 2003-2023 : Zhengzhou Howann Machinery Co., Ltd All Rights Reserved.