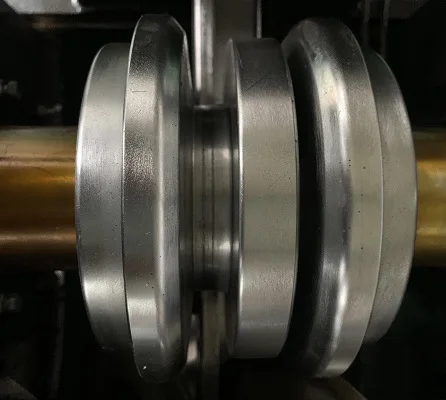

45 # steel

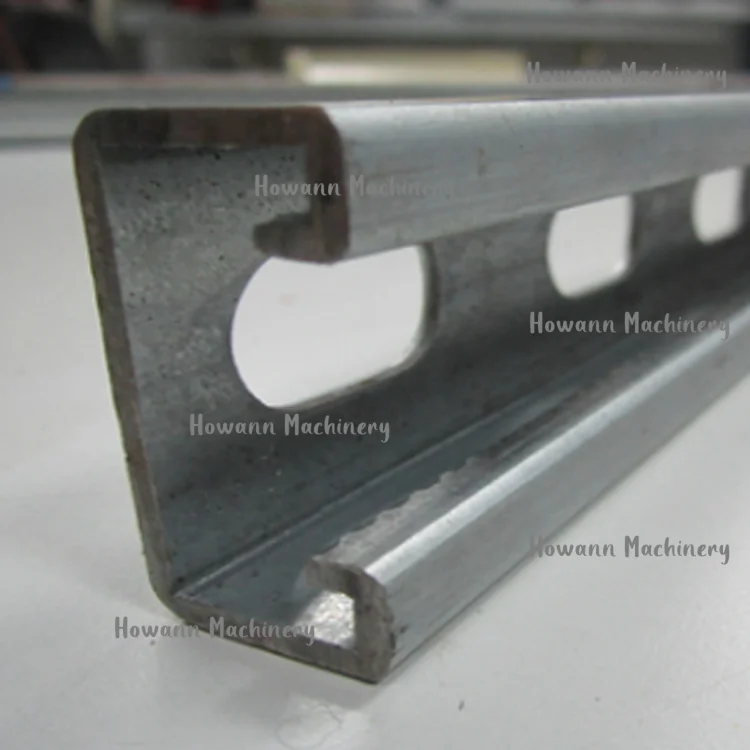

High-precision machining rollers Does not hurt the galvanized surface of the profile

Products Categories

Feature Products

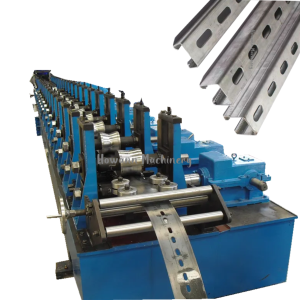

U C Profile Roll Forming Solar Bracket Making Equipment

Photovoltaic Strut Support U C Profile Roll Forming Machine – Solar bracket manufacturing, 80m/min production, Delta PLC control, manufacturer price by Howann

Machine Video

Machine Specification

|

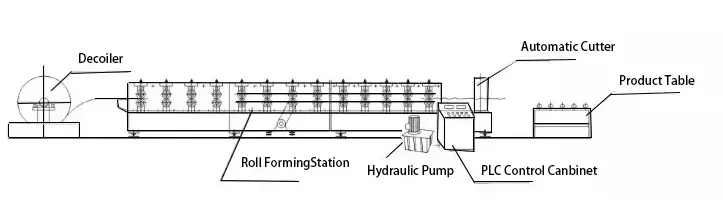

Photovoltaic bracket production line configuration components

|

||

|

Name

|

Quantity

|

Units

|

|

Double head hydraulic uncoiler

|

1

|

Set

|

|

Rotary punching device(Maximum speed 80m/min)

|

1

|

Set

|

|

Siemens motor drive

|

1

|

Set

|

|

Adjustable feeding platform

|

1

|

Set

|

|

Roll forming system

|

1

|

Set

|

|

Non-stop cutting

|

1

|

Set

|

|

Hydraulic system

|

1

|

Set

|

|

Delta PLC electronic control system

|

1

|

Set

|

|

Supporter/Automatic Stacker

|

1

|

Set

|

Machine Features

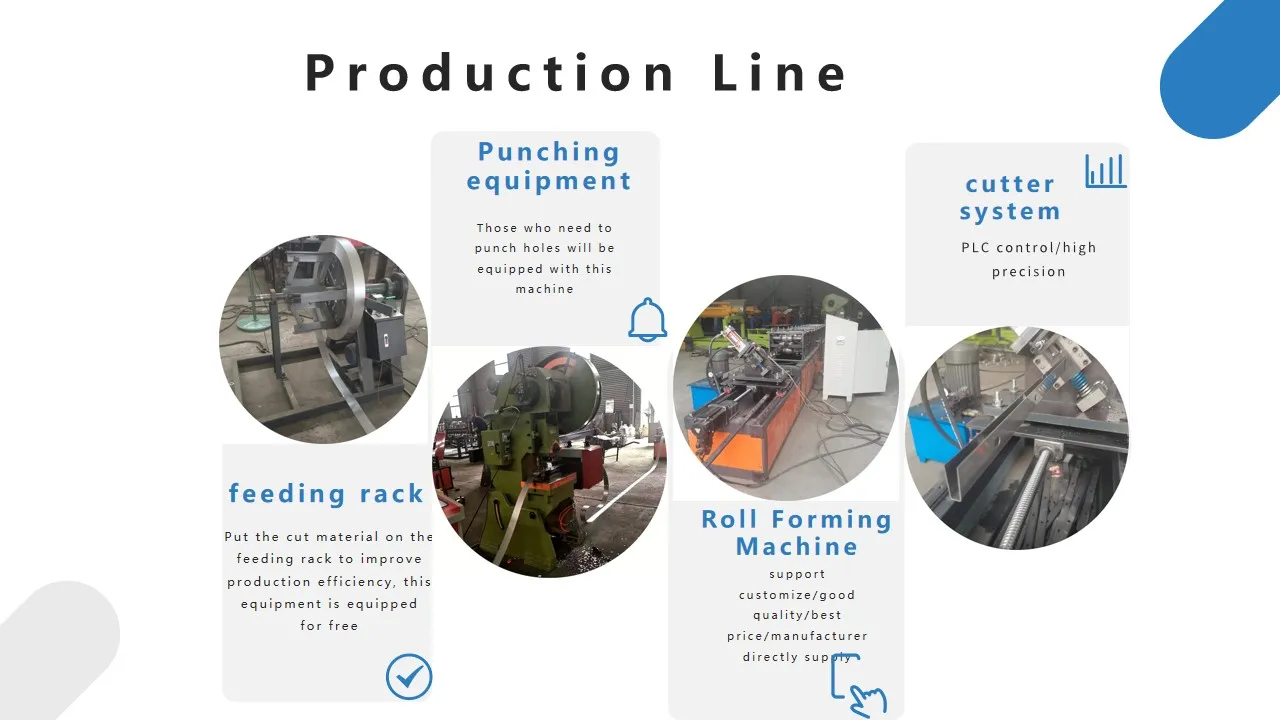

Solar photovoltaic bracket roll forming machine is a full automatic line to produce the solar photovoltaic bracket strut ,which is a special bracket designed for placing, installing and fixing solar panels in solar photovoltaic power generation system.

Packaging Type Of Bag

Machine Function

Machine Option

45 # steel

Shear material:Gr12 hydraulic shear

3kw pumping station Hydraulic station pressure at 10-12mpa 46# hydraulic oil Size: 500*400*700mm

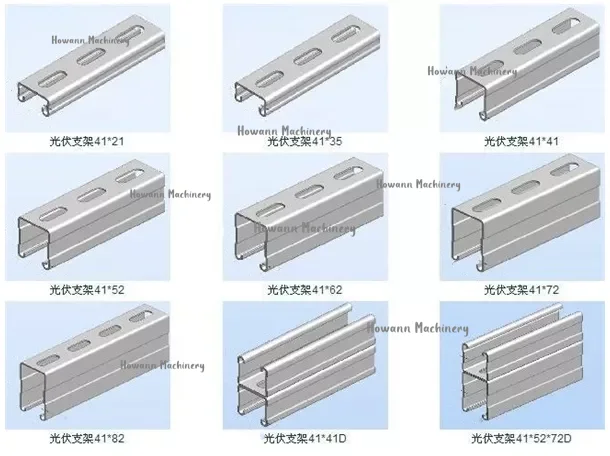

Product Final Shape can be customized.

The board surface is flat, no wrinkles, no scratches, and the molding effect is good.

We can process the machine according to customers’ demand and also can give professional suggestions if the customers need~

Machine Application

Related Products

CONTACT US

Featured Categories

Contact Us

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

© Copyright – 2003-2023 : Zhengzhou Howann Machinery Co., Ltd All Rights Reserved.