Professional C U purlin roll forming machine produces GI steel purlins with 15m/min speed. Handles 0.3-1.2mm materials, PLC control, 1-year warranty. CE certified. Free quotation!

C U Purlin Roll Forming Machine: Advanced Steel Purlin Manufacturing Solution

Revolutionizing Construction Purlin Production with Precision Roll Forming Technology

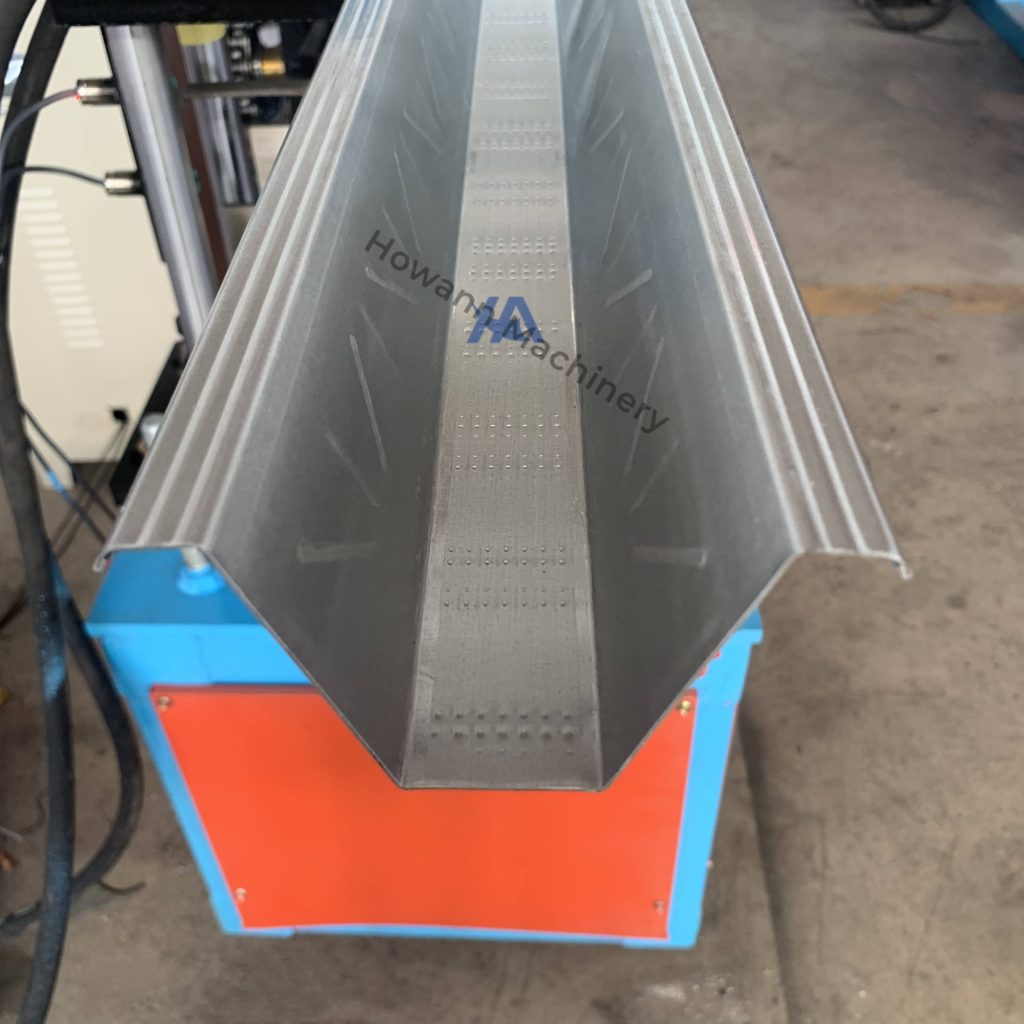

In modern construction industry, steel purlins are essential structural components that provide critical support for roofs and walls. Traditional manufacturing methods for C and U shaped purlins often result in inconsistent quality and low production efficiency. The C U Purlin Roll Forming Machine represents a significant technological advancement, offering complete automation from coil feeding to finished purlin output with exceptional precision and speed.

This automated production system specializes in manufacturing high-quality C and U shaped purlins through a continuous roll forming process. U Purlin Roll Forming Machine.With production speeds reaching 15 meters per minute and the capability to handle GI material thickness from 0.3mm to 1.2mm, this machine is engineered for construction material manufacturers seeking to enhance their production capabilities while maintaining the highest quality standards.

Technical Specifications: Industrial-Grade Performance

Core Machine Parameters

| Parameter | Specification |

|---|---|

| Production Speed | 15 meters/minute |

| Material Thickness | 0.3-1.2mm GI steel coils |

| Machine Weight | 4000 kg |

| Power Requirement | 4.5KW industrial motor |

| Voltage Options | 380V/3Phase or customizable |

| Control System | PLC Automatic Control |

| Shaft Material | 45# High Grade Steel |

| Cutting Blade | Cr12 Mold Steel |

| Warranty Period | 1 year |

Advanced Technical Features

- High-Precision Forming: Multiple roll stations ensure accurate C and U profiles

- PLC Control System: Touchscreen interface with programmable recipes

- Hydraulic Punching: Precision punching system for connection holes

- Automatic Operation: Continuous production from coil to finished purlins

- Material Compatibility: Handles GI and other steel materials

- Safety Systems: Comprehensive safety guards and emergency stops

Key Advantages for Construction Material Manufacturers

Production Efficiency Comparison

| Aspect | Traditional Manufacturing | C U Purlin Roll Forming Machine |

|---|---|---|

| Production Rate | 5-8 meters/minute | 15 meters/minute |

| Labor Requirement | 3-4 operators | 1-2 operators |

| Quality Consistency | ±1.0mm tolerance | ±0.2mm tolerance |

| Material Utilization | 85-90% | 95-98% |

| Daily Output | 2,400-3,800 meters | 7,200 meters |

Quality and Operational Benefits

- Structural Integrity: Precisely formed purlins with consistent dimensions

- Cost Efficiency: Reduced labor costs and material waste

- Production Scalability: Capable of meeting large-volume orders

- Quick Changeover: Digital programs enable fast specification changes

- Quality Assurance: Each purlin meets strict construction standards

Applications in Construction Industry

Building Types and Applications

- Industrial Buildings: Warehouse roof and wall support systems

- Commercial Structures: Shopping malls and office buildings

- Agricultural Facilities: Barns and storage buildings

- Residential Construction: Modern steel frame houses

Customization Services Available

- Graphic Customization: Tailored visual elements and branding

- Packaging Customization: Specific packaging requirements

- Logo Customization: Brand identification options

- Technical Customization: Adapted to specific project needs

Investment Analysis: Maximizing ROI

Cost-Benefit Breakdown

- Machine Investment: ¥96,552-¥110,346 (quantity dependent)

- Daily Production Capacity: 7,200 meters (8-hour shift)

- Labor Cost Reduction: Significant savings in operational costs

- Material Savings: Improved yield through precision manufacturing

- Payback Period: 6-9 months for most operations

Quality Assurance Features

- Rigid Construction: 4000kg weight ensures stability during operation

- Precision Engineering: Accurate forming for perfect purlin quality

- Durable Components: Quality materials for long service life

- Comprehensive Testing: Each machine undergoes rigorous quality checks

Certification and Compliance

Our C U Purlin Roll Forming Machine meets international standards:

- Quality Standards: Manufactured to strict quality requirements

- Safety Compliance: Meets industrial safety standards

- Performance Validation: Tested for reliable operation

- Documentation: Complete technical specifications provided

Technical Support and Services

Comprehensive Support Package

- Installation Guidance: Detailed setup instructions and support

- Operator Training: Comprehensive operation training program

- Maintenance Support: Scheduled service and spare parts availability

- Technical Assistance: Remote support for operational queries

Supplier Capabilities

- Zhengzhou Howann Machinery Co., Ltd.: Established manufacturer with 4 years experience

- Quality Assurance: Mechanical test reports and factory inspection available

- Customization Options: Light to heavy customization available

- Global Logistics: Worldwide shipping solutions

Frequently Asked Questions

Q: What materials can the machine process?

A: The machine handles GI steel coils with thickness from 0.3mm to 1.2mm, suitable for various construction applications.

Q: How quickly can production specifications be changed?

A: Most changes can be implemented within 15-30 minutes through the PLC control system.

Q: What is the warranty coverage?

A: The machine comes with a 1-year warranty covering manufacturing defects.

Q: Do you provide installation supervision?

A: Yes, we offer installation guidance and can provide video factory inspection services.

Ready to Enhance Your Purlin Production?

Our C U Purlin Roll Forming Machine offers professional-grade performance for construction material manufacturers. With advanced features and reliable operation, this machine will help you achieve new levels of production efficiency and product quality.

Contact us today for:

- Detailed machine specifications

- Customized solution discussion

- Pricing information

- Technical support